Description

The Altrad Belle micro-trenching system has been specifically designed to provide a faster, less disruptive, more cost-efficient, and more environmentally friendly method of creating shallow, narrow trenches in existing hardscapes associated with installing pipework, ducting, induction loops, fibre optics, cabling, etc. Such works often require lengths of small-diameter products being submerged at a shallow level below ground and the surface making good thereafter.

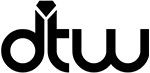

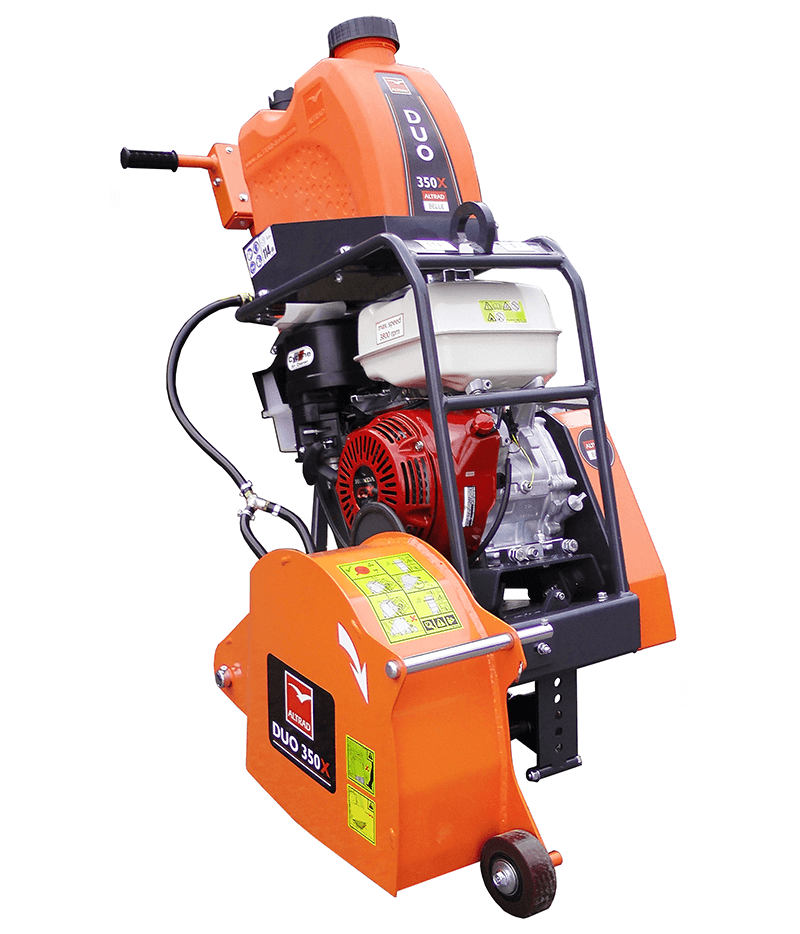

Historically, such works typically involved two sawn edges a digger bucket width apart, which was slow, time-consuming, more disruptive, and required far greater ground and surface disruption. The cost of reinstatement and materials was also greater too. The Belle DUO 350X is a twin-bladed 14” floor saw enabling two cuts (a fixed 100mm apart) to be produced simultaneously and in constant parallel to each other. The maximum depth of cut achievable with a DUO350X is 120mm. The cut produced is then excavated, works conducted and made good, with the specially adapted RTX60M with its choice of custom-engineered extension feet used to compact the narrow, shallow trench produced.

Our package consists of a Belle DUO 350X twin-blade floor saw complete with a Belle RTX60M trench rammer at an attractive, cost-reduced price. As part of the micro-trenching system, Altrad Belle has created the DUO 350X, a 14” dual-bladed floor saw with a fixed 100mm cutting width, enabling a fixed width shallow trench to be efficiently and consistently produced, the perfect partner and accompaniment for use with the RTX60M.

The Belle RTX60M trench rammer features a custom-engineered range of interchangeable feet specifically designed for micro-trenching applications, allowing the shallow, narrow trenches produced to be quick and efficiently compacted. There are four dedicated extension feet that have been produced for the RTX 60M for micro-trenching. They are 80 x 160mm, 80 x 260mm, 100 x 160mm, and 100 x 325mm. Alternatively, the same rammer can also be used with a choice of 3 standard rammer feet (165, 230, or 280mm wide).

The DUO350X twin-bladed floor saw has been specifically adapted to enable two 14”/350mm diameter diamond blades to be mounted and used simultaneously to produce a fixed 100mm wide cut, with each cut in constant parallel to the other. The maximum depth of cut achievable is 120mm. This is ideal for efficiently producing the cuts required to produce the narrow and shallow trench required to install microducting, cabling, fibre optics, induction loops, etc.

Producing micro trenches that are narrower and shallower causes less environmental disruption and requires fewer materials to infill and reinstate too. The consequential benefits are many, as are the cost and labour savings.

*The DUO350X can also be used with a single blade and used as a conventional 14” floor saw.

Both the DUO350X and RTX60M rammer have low Hand Arm Vibration enabling them to be used in combination for greater periods of safe use for maximum productivity.

Key Features:

- Twin-bladed floor saw for simultaneous, parallel cuts

- Custom-engineered extension feet for trench rammer

- Reduced environmental disruption and material use

- Cost and labour-saving micro-trenching solution

- Low Hand Arm Vibration for increased safe usage periods

Reviews

There are no reviews yet.